VSH Shurjoint

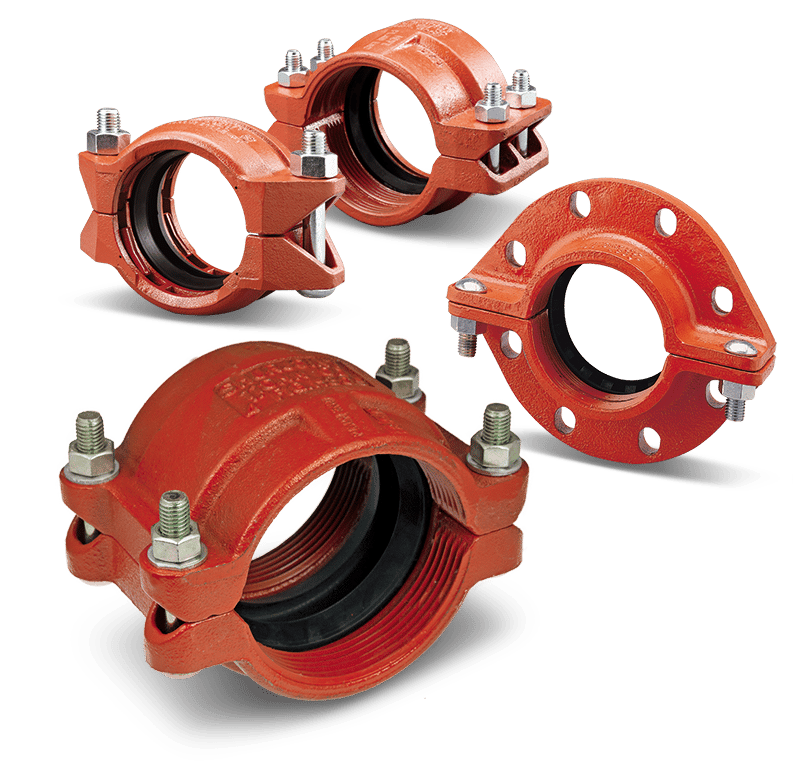

The Shurjoint grooved piping system is one of the most advanced, versatile, economical and reliable systems available today. After the pipe ends are grooved a gasket is mounted over the pipe ends. The coupling segments are then placed over the gasket and the bolts and nuts are fastened resulting in a secure and leak free joint. A coupling can be installed 3 – 4 times faster than a comparable welded or brazed joint and there is no need for a flame or welding torch on the job site.

A grooved mechanical coupling can be installed by fastening a pair of bolts and nuts while using only a wrench or spanner, whereas a comparable flanged joint requires the fastening of many bolts and nuts with a pair of wrenches. The grooved system allows for easy material take-offs and unlike a threaded system, there is no need to allow for added pipe length for thread engagement. With removal of just a few bolts one can easily access the system for cleaning, maintenance, changes and or system expansion.

Helpful Information to Ensure Proper Assembly

Some couplings and components require the housing bolt pads to make metal-to-metal contact for proper assembly, while others require a specific bolt torque while maintaining equal bolt pad gaps. The icons and information below will help to identify those items to ensure proper assembly. Read and follow all installation instructions for the component being installed.

Metal-to-metal contact: Tighten bolts and nuts until bolt pads make metal-to-metal contact. After metal-to-metal contact is achieved, tighten nuts by another one quarter or one half turn to make sure the bolts and nuts are snug and secure. No torque wrench is required. Excessive torque may lead to bolt or joint failure.

Torque required! Bolts and nuts must always be tightened to the required torque by using a torque wrench. Normally there will be some gaps seen between the bolt pads after the

bolts and nuts are fully tightened. Bolt pad gaps should be equal on both sides of the coupling. Models that require torque tightening include 2” through 4” of model XH-1000, all sizes of models

XH-70EP, SS-7X and 79 couplings.

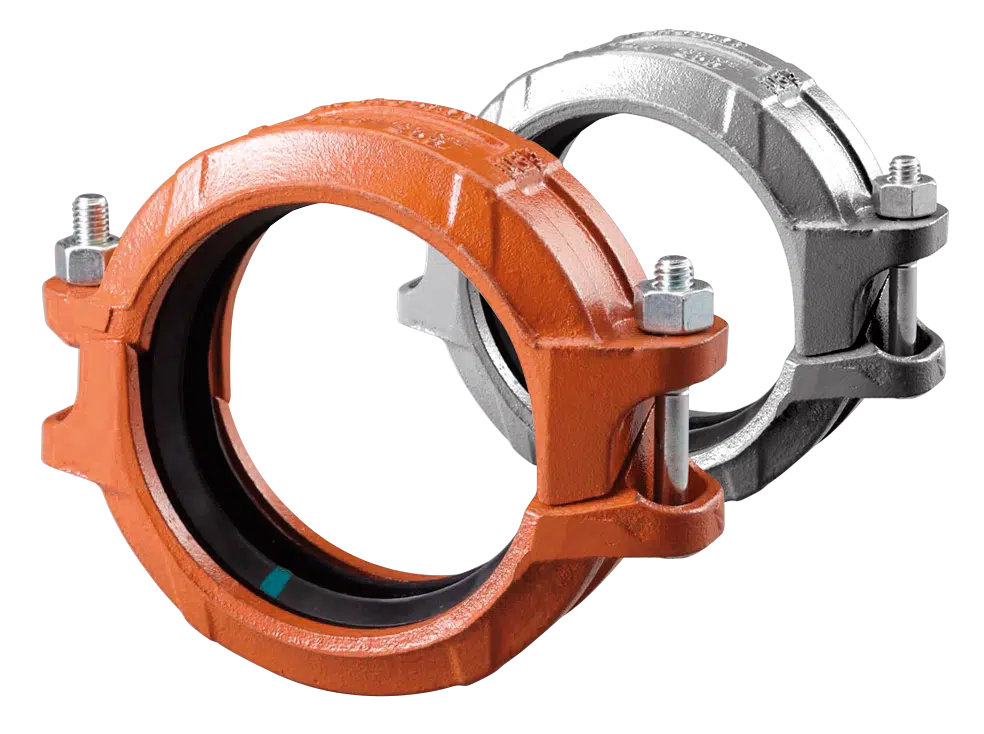

Rigid and Flexible couplings

Grooved mechanical couplings (GMC) are available in both rigid and flexible models. A rigid coupling is used in applications where a rigid joint is desired, similar to that of a traditional flanged, welded, and or threaded connection. To be considered rigid, a coupling would allow less

than one degree of deflection or angular movement.

Flexible couplings are designed to accommodate axial displacement, rotation and a minimum one degree of angular movement. Flexible couplings are used in applications that call for curved or deflected layouts and or when systems are exposed to outside forces beyond normal static conditions, such as seismic events or where vibration and or noise attenuation are a concern.

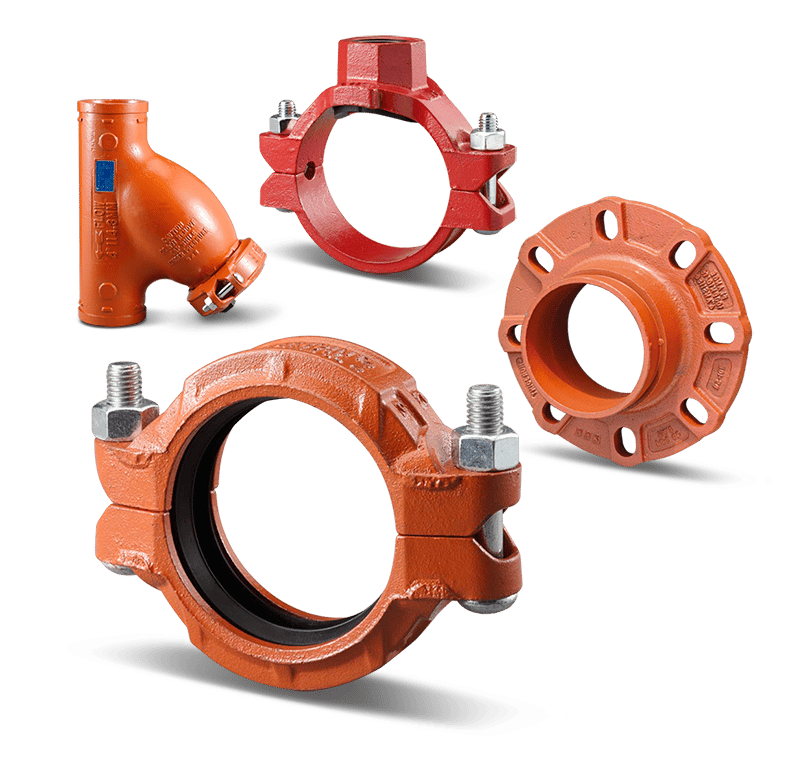

Shurjoint offers a wide range of grooved-end fittings in sizes through 24” (600 mm). Fittings are available in a number of styles and configurations to support a variety of applications. Shurjoint grooved-end fittings are manufactured and designed to meet ASTM F1548 and ANSI/AWWA C606 requirements for use with grooved mechanical couplings conforming to ASTM F1476. For sizes not specified in these standards, please refer to

applicable groove specifications shown in catalog.

Most fittings are provided in ductile iron conforming to ASTM A536 Gr. 65-45-12. Some styles

and sizes larger than 14” (350 mm) are fabricated from carbon steel pipe to ASTM A53 Gr. B or fabricated of segmentally welded steel of the same or equivalent grade. Fittings are painted orange or red, or as an option can be supplied hot-dip galvanized or epoxy coated.