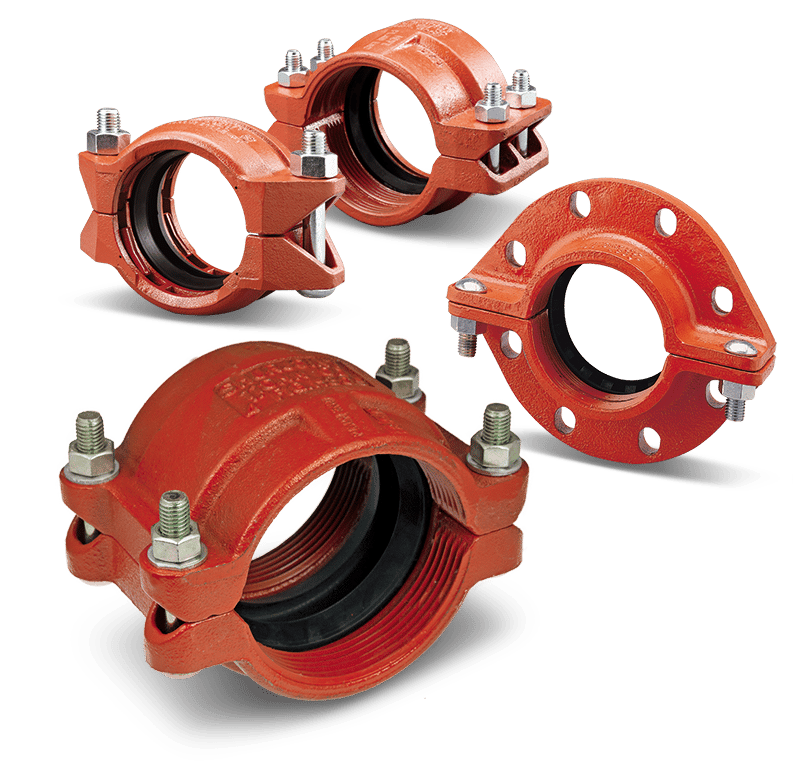

VSH Shurjoint Plain-End

Shurjoint plain-end couplings are non-grooved mechanical pipe joining components and excellent alternatives where pipe is difficult to groove or when grooving is not the preferred method. The processing of a roll groove on pipe becomes more difficult as the pipe O.D. and or wall thickness increases. Roll grooving pipe

larger than 14” (350 mm) requires proper tools and equipment. Pipe having a wall thickness greater than 0.375” (9.5 mm) may not be practical to roll groove.

Plain-End Piping System for Steel Pipe

The Shurjoint Model 79 Wildcat Coupling is designed to mechanically join plain-end or beveled end carbon steel pipe. The Wildcat couplings can be used for a variety of applications including mining, process piping, manifold piping and oil field services. The Wildcat couplings feature case-hardened jaws* within the housings and large diameter heat treated track bolts that when tightened securely grip the pipe surface. As with grooved couplings, a C-shaped rubber gasket effectively seals the pipe ends (*For sizes larger than 14” (350 mm), jaws are made of 17-4PH stainless steel.)

The Model 79 coupling is recommended for use on carbon steel pipe with a hardness less than HB150, not recommended for stainless steel, plastic, HDPE, cast iron or other brittle pipe. Gaskets are available either in Grade E EPDM for water services of -29°F to +230°F (-34°C to + 110°C) or Grade T Nitrile for oil services -20°F to +180°F (-29°C to +82°C).

Plain-End Piping System for HDPE pipe

Shurjoint HDPE couplings provide a fast and easy way to mechanically join HDPE pipe. A series of sharply machined teeth securely grip the pipe as the bolts are tightened, resulting in a leak-free joint. The Shurjoint joining method eliminates the need for costly heat fusion equipment. The highly restrained joint allows long lengths of pipe to be pulled from one area to another. With the removal of a few bolts one can easily access the system for cleaning, maintenance, changes and or system expansion.

Shurjoint HDPE couplings are designed to join IPS HDPE pipe, R32.5 to 7.3, conforming to ASTM D2513, D3350 and/or ANSI/AWWA C901, and ISO HDPE pipe, SDR 9 to 26, conforming to ISO 4427-1/2. As the ductile iron coupling is much stronger than HDPE pipe itself, pressure ratings of HDPE couplings are determined by the pressure rating of HDPE pipe used. Pressure ratings of HDPE pipe vary depending on DR or SDR (standard dimension ratio) and design stress of the material.