heating

cooling

compressed air

sprinkler

dry fire main

fire protection

commercial building

industry

FM

UL

ULc

item

size

dimensions

weight

packaging

gtin

item

size

76.1x60.3 orange

dimensions

89x76x76 mm

weight

0.72 kg

packaging

-

gtin

08711985436624

item

size

76.1x60.3 galvanized

dimensions

89x76x76 mm

weight

0.72 kg

packaging

-

gtin

08711985436617

item

size

88.9x48.3 orange, fab.

dimensions

89x89x89 mm

weight

0.6 kg

packaging

-

gtin

-

item

size

88.9x60.3 orange

dimensions

89x89x89 mm

weight

1 kg

packaging

-

gtin

08711985436631

item

size

88.9x60.3 galvanized

dimensions

89x89x89 mm

weight

1 kg

packaging

-

gtin

08711985436648

item

size

88.9x73 orange

dimensions

89x89x89 mm

weight

1 kg

packaging

-

gtin

04710574426750

item

size

88.9x76.1 orange

dimensions

89x89x89 mm

weight

1 kg

packaging

-

gtin

08711985436655

item

size

88.9x76.1 galvanized

dimensions

89x89x89 mm

weight

1 kg

packaging

-

gtin

08711985436662

item

size

114.3x60.3 orange

dimensions

102x114x114 mm

weight

1.29 kg

packaging

-

gtin

08711985436679

item

size

114.3x60.3 galvanized

dimensions

102x114x114 mm

weight

1.29 kg

packaging

-

gtin

08711985436686

item

size

114.3x73 galvanized

dimensions

102x114x114 mm

weight

1.5 kg

packaging

-

gtin

-

item

size

114.3x76.1 orange

dimensions

102x114x114 mm

weight

1.5 kg

packaging

-

gtin

08711985436693

item

size

114.3x76.1 galvanized

dimensions

102x114x114 mm

weight

1.5 kg

packaging

-

gtin

08711985436709

item

size

114.3x88.9 orange

dimensions

102x114x114 mm

weight

1.3 kg

packaging

-

gtin

08711985436716

item

size

114.3x88.9 galvanized

dimensions

102x114x114 mm

weight

1.3 kg

packaging

-

gtin

08711985436723

item

size

139.7x88.9 orange

dimensions

102x140x140 mm

weight

2.36 kg

packaging

-

gtin

08711985436730

item

size

139.7x88.9 red, fab.

dimensions

102x140x140 mm

weight

2.36 kg

packaging

-

gtin

-

item

size

139.7x88.9 galvanized

dimensions

102x140x140 mm

weight

2.36 kg

packaging

-

gtin

08711985478495

item

size

139.7x114.3 orange

dimensions

102x140x140 mm

weight

2.8 kg

packaging

-

gtin

08711985436747

item

size

139.7x114.3 galvanized

dimensions

102x140x140 mm

weight

2.8 kg

packaging

-

gtin

08711985478501

item

size

141.3x73 red, fab.

dimensions

102x141x141 mm

weight

2.09 kg

packaging

-

gtin

-

item

size

141.3x88.9 orange, fab.

dimensions

102x141x141 mm

weight

2.36 kg

packaging

-

gtin

-

item

size

141.3x88.9 red, fab.

dimensions

102x141x141 mm

weight

2.36 kg

packaging

-

gtin

-

item

size

141.3x114.3 orange

dimensions

102x141x141 mm

weight

2.8 kg

packaging

-

gtin

-

item

size

141.3x114.3 galvanized

dimensions

102x141x141 mm

weight

2.8 kg

packaging

-

gtin

-

item

size

165.1x60.3 orange

dimensions

102x165x165 mm

weight

2 kg

packaging

-

gtin

08711985478440

item

size

165.1x60.3 galvanized

dimensions

102x165x165 mm

weight

2 kg

packaging

-

gtin

08711985478518

item

size

165.1x88.9 orange

dimensions

102x165x165 mm

weight

2.64 kg

packaging

-

gtin

08711985436754

item

size

165.1x88.9 galvanized

dimensions

102x165x165 mm

weight

2.64 kg

packaging

-

gtin

08711985478525

item

size

165.1x114.3 orange

dimensions

102x165x165 mm

weight

2.46 kg

packaging

-

gtin

08711985436761

item

size

165.1x114.3 galvanized

dimensions

102x165x165 mm

weight

2.46 kg

packaging

-

gtin

08711985478532

item

size

165.1x139.7 orange

dimensions

102x165x165 mm

weight

3.07 kg

packaging

-

gtin

08711985436778

item

size

165.1x139.7 galvanized

dimensions

102x165x165 mm

weight

3.07 kg

packaging

-

gtin

08711985478549

item

size

168.3x60.3 orange

dimensions

102x168x168 mm

weight

2 kg

packaging

-

gtin

08711985436785

item

size

168.3x60.3 galvanized

dimensions

102x168x168 mm

weight

2 kg

packaging

-

gtin

08711985478556

item

size

168.3x73 red, fab.

dimensions

102x168x168 mm

weight

3.07 kg

packaging

-

gtin

-

item

size

168.3x88.9 orange

dimensions

102x168x168 mm

weight

3.5 kg

packaging

-

gtin

08711985436792

item

size

168.3x88.9 galvanized

dimensions

102x168x168 mm

weight

3.5 kg

packaging

-

gtin

08711985436808

item

size

168.3x114.3 orange

dimensions

102x168x168 mm

weight

2.65 kg

packaging

-

gtin

08711985436815

item

size

168.3x114.3 galvanized

dimensions

102x168x168 mm

weight

2.65 kg

packaging

-

gtin

08711985436822

item

size

168.3x139.7 orange

dimensions

102x168x168 mm

weight

3.07 kg

packaging

-

gtin

08711985478457

item

size

168.3x139.7 galvanized

dimensions

102x168x168 mm

weight

3.07 kg

packaging

-

gtin

08711985478563

item

size

168.3x141.3 orange

dimensions

102x168x168 mm

weight

4.5 kg

packaging

-

gtin

-

item

size

168.3x141.3 galvanized

dimensions

102x168x168 mm

weight

4.5 kg

packaging

-

gtin

-

item

size

219.1x114.3 orange

dimensions

127x219x219 mm

weight

6.6 kg

packaging

-

gtin

08711985436839

item

size

219.1x114.3 galvanized

dimensions

127x219x219 mm

weight

6.6 kg

packaging

-

gtin

08711985478570

item

size

219.1x139.7 orange, fab.

dimensions

127x219x219 mm

weight

6.6 kg

packaging

-

gtin

-

item

size

219.1x139.7 galvanized, fab.

dimensions

127x219x219 mm

weight

6.6 kg

packaging

-

gtin

-

item

size

219.1x165.1 orange

dimensions

127x219x219 mm

weight

5.1 kg

packaging

-

gtin

08711985436846

item

size

219.1x165.1 galvanized

dimensions

127x219x219 mm

weight

5.1 kg

packaging

-

gtin

08711985478587

item

size

219.1x168.3 orange

dimensions

127x219x219 mm

weight

4.88 kg

packaging

-

gtin

08711985436853

item

size

219.1x168.3 galvanized

dimensions

127x219x219 mm

weight

4.88 kg

packaging

-

gtin

08711985436860

item

size

273x114.3 galvanized

dimensions

152x273x273 mm

weight

12 kg

packaging

-

gtin

08711985478594

item

size

273x165.1 orange

dimensions

152x273x273 mm

weight

11.5 kg

packaging

-

gtin

08711985478464

item

size

273x165.1 galvanized

dimensions

152x273x273 mm

weight

11.5 kg

packaging

-

gtin

08711985478600

item

size

273x168.3 orange

dimensions

152x273x273 mm

weight

11.5 kg

packaging

-

gtin

08711985478471

item

size

273x168.3 galvanized

dimensions

152x273x273 mm

weight

11.5 kg

packaging

-

gtin

08711985478617

item

size

273x219.1 orange

dimensions

178x273x273 mm

weight

12.17 kg

packaging

-

gtin

08711985437898

item

size

273x219.1 galvanized

dimensions

178x273x273 mm

weight

12.17 kg

packaging

-

gtin

08711985437904

item

size

323.9x219.1 orange

dimensions

178x324x324 mm

weight

18.5 kg

packaging

-

gtin

08711985437911

item

size

324x219.1 galvanized

dimensions

178x324x324 mm

weight

18.5 kg

packaging

bag (1 pce)

gtin

08711985478624

item

size

324x273 orange

dimensions

178x324x324 mm

weight

20 kg

packaging

bag (1 pce)

gtin

08711985478488

item

size

323.9x273 galvanized

dimensions

178x324x324 mm

weight

20 kg

packaging

bag (1 pce)

gtin

08711985478631

item

size

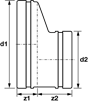

d1

DN1

l1

z1

d2

DN2

l2

item

171515245003size

139.7x114.3 galvanized

d1

139.7

DN1

DN125

l1

51

z1

51

d2

114.3

DN2

DN100

l2

51

item

171515530001size

141.3x88.9 orange, fab.

d1

141.3

DN1

DN125

l1

51

z1

51

d2

88.9

DN2

DN80

l2

51

item

171515545003size

141.3x114.3 galvanized

d1

141.3

DN1

DN125

l1

51

z1

51

d2

114.3

DN2

DN100

l2

51

item

171516245003size

165.1x114.3 galvanized

d1

165.1

DN1

DN150

l1

51

z1

51

d2

114.3

DN2

DN100

l2

51

item

171516252003size

165.1x139.7 galvanized

d1

165.1

DN1

DN150

l1

51

z1

51

d2

139.7

DN2

DN125

l2

51

item

171516545003size

168.3x114.3 galvanized

d1

168.3

DN1

DN150

l1

51

z1

51

d2

114.3

DN2

DN100

l2

51

item

171516552003size

168.3x139.7 galvanized

d1

168.3

DN1

DN150

l1

51

z1

51

d2

139.7

DN2

DN125

l2

51

item

171516555003size

168.3x141.3 galvanized

d1

168.3

DN1

DN150

l1

51

z1

51

d2

141.3

DN2

DN125

l2

51

item

171518545003size

219.1x114.3 galvanized

d1

219.1

DN1

DN200

l1

64

z1

64

d2

114.3

DN2

DN100

l2

64

item

171518552001size

219.1x139.7 orange, fab.

d1

219.1

DN1

DN200

l1

64

z1

64

d2

139.7

DN2

DN125

l2

64

item

171518552003size

219.1x139.7 galvanized, fab.

d1

219.1

DN1

DN200

l1

64

z1

64

d2

139.7

DN2

DN125

l2

64

item

171518562003size

219.1x165.1 galvanized

d1

219.1

DN1

DN200

l1

64

z1

64

d2

165.1

DN2

DN150

l2

64

item

171518565003size

219.1x168.3 galvanized

d1

219.1

DN1

DN200

l1

64

z1

64

d2

168.3

DN2

DN150

l2

64

color

silver, red, orange

materials

cast iron, steel (ASTM A536 65-45-12, ASTM A53 Grade B)

finishing

galvanised, varnished

manufacturer

Shurjoint

shape

Excentric, reducer

connection type

groove (fitting)

product group

fittings (demountable)

ETIM class

EC003024 Fitting with 2 connections

intrastat code

73071910

country of origin

Taiwan

brand

VSH

series

Shurjoint

type

7151

image | png

7151-Combi

diagram | png

Diagram

submittal sheet | pdf

Datasheet

installation- & maintenance document | pdf

VSH Shurjoint Installation Handbook

image | png

7151

image | png

7151-GV

certifications | pdf

FM

certifications | pdf

UL

certifications | pdf

ULc

installation- & maintenance document | pdf

VSH Shurjoint instructions

label

value

label

ETIM class

label

Shape

value

Straight

label

Model

value

1-part

label

Reducing

value

Yes

label

Eccentric

value

Yes

label

System specific

value

No

label

Connection 1

value

Groove

label

Connection 2

value

Groove

label

With buffer stud

value

No

label

High tensile strength

value

Yes

label

With sealing rings/gaskets

value

No

label

Capped

value

No

label

With connection indicator

value

No

label

With drain valve

value

No

label

With de-aerator

value

No

label

LPCB quality mark

value

No

label

VdS quality mark

value

No

label

DVGW quality mark for gas

value

No

label

DVGW quality mark for water

value

No

label

Certified according to NF 545

value

No

label

KIWA certified

value

No

label

Gastec QA mark

value

No

label

KOMO certified

value

No

label

Gastec QA - AR 214 (H2)

value

No

we are here to help

product selected products selected

you can compare up to 2 products

you can compare up to 4 products